Why cleaning with steam

In order to comply with its detection limits, trace analysis requires not only precise analysis but also clean vessels to prevent sample contamination. The ADA-1 assists in this by carefully cleaning a wide variety of vessels after use, regardless of whether they are made of glass or plastic.

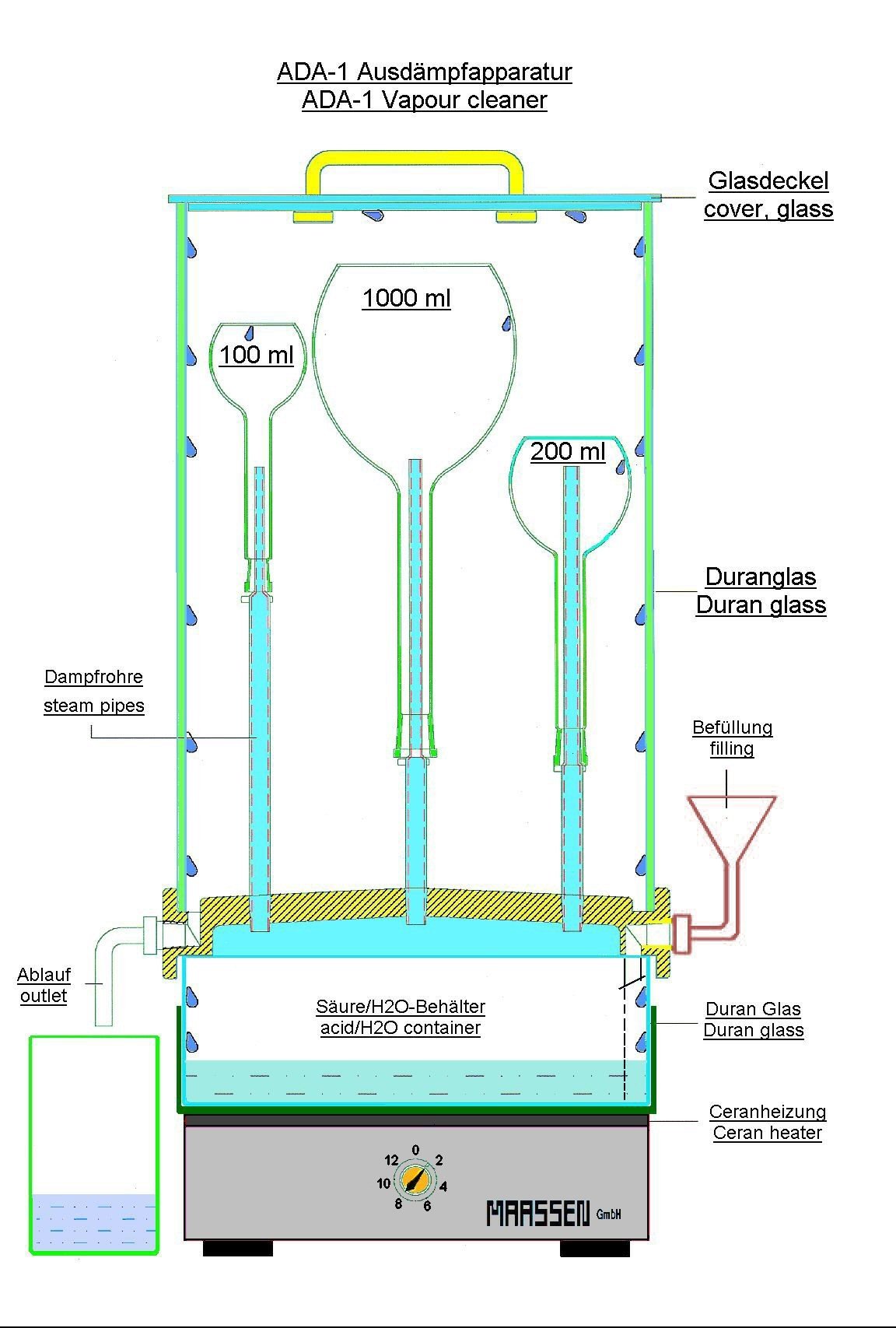

he cleaning apparatus ADA-1 cleans vessels such as flasks, beakers, syringes, and others from the inside using hot acid or water vapor. This process is significantly more effective than boiling, which is primarily based on two effects:

1. Steam effectively rinses off

2. The surface of the vessel is saturated with the ions of the cleaning solution.

This results in a reduction of losses due to adsorption to the vessel wall from analytical solutions, and the cleaned vessels are suitable for trace analysis.

The ADA-1 is designed for the cleaning and pretreatment of vessels made of quartz glass, Teflon (PTFE/PFA), ceramics, or borosilicate glass.

Construction

A modified heating plate with a ceramic surface heats the glass bowl placed on it, into which approximately 4-5 liters of acid, acid mixture, or high-purity water can be filled. The evaporating solution is directed through glass tubes directly into the vessels to be cleaned. The condensate is channeled through the PTFE system plate into a collection vessel and can be reused after cleaning by distillation or subboiling. The bowl holds enough acid for several cleaning cycles. The duration of the cleaning process depends on the degree of contamination of the vessels, typically around 1 to 3 hours. The ADA-1 does not need to be cooled during operation; normal room temperature is sufficient for adequate condensation. A separate timer can interrupt the power supply after the cleaning process. However, it is essential to ensure that the glass bowl does not run dry.

2x 15 steam pipes are included: a 6 mm opening for small tubes or sample containers and an 8 mm opening for larger flasks or beakers. Optionally, steam pipes with a 10 mm opening are also available. The ADA-1 can be variably equipped by simply rearranging the steam pipes, although it is recommended to use only similar pipes per cleaning process due to the uniform steam pressure. A maximum of 25 smaller containers or three 1 L flasks can be cleaned simultaneously. Depending on their position, the steam pipes have a distance of about 20 – 25 mm from each other. Unused steam openings can be easily sealed with the included glass stoppers. If needed, the PTFE plate can also be expanded for up to 49 cleaning positions, for example, if you need to clean many small vessels at once.

In case of excessive steam development, it may occur that the resulting steam pressure becomes too high and steam escapes. Therefore, for safety reasons, we recommend operating the steam distillation apparatus under a fume hood, especially when it is used with acids.

Glass vessels are usually dry after the cleaning and cooling phase when they are removed from above. The only exception is plastic vessels, which cannot retain heat long enough. In that case, the vessels need to continue drying in the air after removal.

For different applications, different steam pipes are used. Pipe No. 1 in the adjacent image shows the pipe with a 6 mm outlet, suitable for small sample containers. Pipe No. 2 shows the medium size, 8 mm outlet, universally applicable.

Technical Data

Width 32 cm

Deapth 42 cm

Total height including cover 72 cm

Max. height of steam room 44 cm

Inner diameter of steam room 29 cm

Power consumption max. 1600 W in heating phase

5293000 ADA-1 with 25 cleaning stations, each with 15 small + medium steam pipes, external timer

5293000X ADA-1 with 49 cleaning stations, 50 steam pipes of choice, external timer

5293110 small steam pipes (No. 1), 6 mm AD

5293109 medium steam pipes (No. 2), 8 mm AD

5293108 large steam pipes (without image, otherwise as No. 2), 10 mm AD

5293100 glass bowl

5293301 modified heating field with spill protection

5293114 glass stopper to close unused steam openings

5293103 glass lid with handle.