To get the best possible results for trace analysis, you need to use very clean vessels to avoid contamination of your samples which may otherwise lead to wrong results.

The ADA-1 exposes contaminated vessels to hot steam from distilled water or dilluted nitric acid. This way of cleaning is much better than just to wash the vessels, because:

1. rinsing with hot steam is highly effective

2. the walls get saturated with the ions of the cleaning solvent

This reduces adsorption effects from analytical solvents at the wall from the cleaned vessels and makes it clean enough for trace analysis.

The ADA-1 is made to clean all kind of vessels made of glass, quartz, PTFE/PFA or ceramics.

Benefits and features

-

leaches metallic ions from the surface of vessels using water or acid vapour - eliminates measurement errors caused by vessel contamination.

-

vessels are continually flushed with fresh acid – contaminated acid will not be reused so you always have the best result. Contaminated acid flows into the container and can be cleaned again by using one of our acid cleaning systems.

-

whole cleaning process can be monitored including the acid level

-

top access to cleaning chamber - easy to handle.

-

no cooling required - saves water consumption.

-

large capacity - simultaneous cleaning of up to 3 x 1 litre flasks.

-

Even small vessels (min. 8 mm ID) can be cleaned continually

-

High Capacity Version can handle up to 49 small vessels at once

-

Glass parts are made of Duran glass

Design

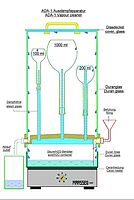

A modified ceran heating unit heats up the glass bowl which can contain enough liquid for several cleaning processes (about 5 L). The system board where up to 49 steam tubes can be plugged in is completely made of PTFE. The steam comes through these tubes to clean the vessels on top. Unused holes need to be closed with the included glass plugs. The steam production can be adjusted by turning the power up or down.

The duration of one cleaning process is depending on the contamination level of your vessels, it us usually done within 1 – 3 hours. The ADA-1 does not need to be cooled. An external timer can shut off the heating element. You only have to make sure that the glass bowl does not run dry and you don’t fill in cool liquids into a hot glass bowl.

Capacity

There are two different sizes available to suit different sizes of vessels, one with 6 mm and one with 8 mm outlet diameter (10 mm on special request). They can be placed individually for best use of the space. The Standard ADA-1 has 25 cleaning places and comes with 2 x 15 steam tubes. The high capacity version has 49 cleaning places and comes with 2 x 25 steam tubes. We recommend only to use the same size of steam tubes in each cleaning process.

Setup

It is possible that hot acid steam can escape, so we recommend to place the whole unit under a fume cupboard and replace the vessels inside only when the system is cooled down.

Vessels made of glass are usually dry after the cleaning process, but other vessels made of synthetic material cool down quite fast, so they may still be wet. Then you have to let them dry in the air.

News

Aktuelles

From the first of November 2023 our company will be in our NEW LOCATION at Ludwigsburg Germany.

All shippments that will arrive later then 1. November only to our new adress:

MAASSEN GmbH

Laboratory products

Ludwigsburger Strasse 77

71696 MOEGLINGEN , Germany

in the search of a pressing tool for a labratory press for CR20xx batteries in individual production? We do have the tool for you, please inquire for more information.

Where high pure acids like HNO3, HCl or HF is needed the PTFE subboiler at hand will be enormously helpful! more Information: here